DELMIA Ortems

Napredno rešenje za planiranje i terminiranje proizvodnje koje se integriše sa vašim postojećim informacionim sistemima.

Kraće vreme isporuke

Raspoređujući vaše proizvodne resurse za sve aktivne projekte DELMIA Ortems pomaže da skratite vreme isporuke i ostvarite kompetitivnu prednost pred zahtevima kupaca i brzim promenama na tržištu.

Budite uvek brži i povoljniji - bez rizika po vaše profitne margine!

Precizno terminiranje

DELMIA Ortems planira vašu proizvodnju precizno i realistično čime doprinosi uspehu svake vaše isporuke.

Ovo je ključno za brzo davanje optimalnih ponuda, održavanje zadovoljstva kupaca i ispunjenje ugovornih obaveza.

Jedna Platforma

Planiranje i terminiranje na jednom centralizovanom mestu za potpunu transparentnost celog vašeg proizvodnog procesa.

Samo tako donosićete pravilne odluke i uvoditi kontinuirana unapređenja.

VIDEO: Kratki uvod u DELMIA ORTEMS rešenje za terminiranje proizvodnje

Ključne prednosti DELMIA Ortems rešenja

Napredno planiranje

Planirajte dugoročno uz analizu faktora kao što su proizvodni kapaciteti, raspoloživost resursa i prognoze tražnje.

Terminiranje resursa

Planirajte detaljne rasporede na osnovu mogućnosti i opterećenja svih vaših proizvodnih resursa - mašina i ljudi.

Praćenje u realnom vremenu

DELMIA Ortems korisnicima može omogućiti praćenje proizvodnje u datom trenutku i uvođenje izmena u cilju povećanja efikasnosti.

Analiza scenarija

Korisnici mogu koristiti softver za proveru alternativnih scenarija za proizvodnju i sagledati njihov uticaj na sve ostale projekte.

Integracija

DELMIA Ortems može se integrisati sa vašim ERP sistemom kako biste dobili besprekoran tok svih podataka po dubini i širini vaše kompanije.

Algoritmi za optimizaciju

Softver obično uključuje i algoritme koji vam pomažu da pronađete najefikasnije i najprofitabilnije opcije za planiranje proizvodnje.

Tri ključne aplikativne primene

3 powerful optimization Engines

Manufacturing Planner

Master Plan schedule

Capacity planning / Load levelling

Synchronized Requirements Planner

Demand, Production and Supply flow synchronization

Multi-level BOM synchronization

Demand driven manufacturing & inventory optimization

Production Scheduler

Detailed sequencing

Campaign management & set-up optimization

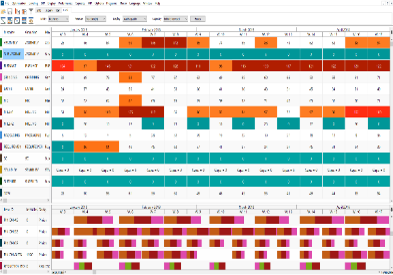

Manufacturing planner

ADVANCED PLANNING FUNCTIONALITIES

- Capacity plans management

- Load leveling and line balancing

- Bottleneck issues highlights

- Delay and anticipation control

- Accurate order promising

- “What if” capabilities & KPIs monitoring

- Alternative routings or sourcing decision support

MULTIPLE DIMENSIONS

- Primary and secondary resources

- Capacity monitoring in load or quantities

- Multiple units including financials

COLLABORATIVE FUNCTIONALITIES

- Multiple planners working simultaneously

- Reference plan for all the organization

- Shared information

- User profiles

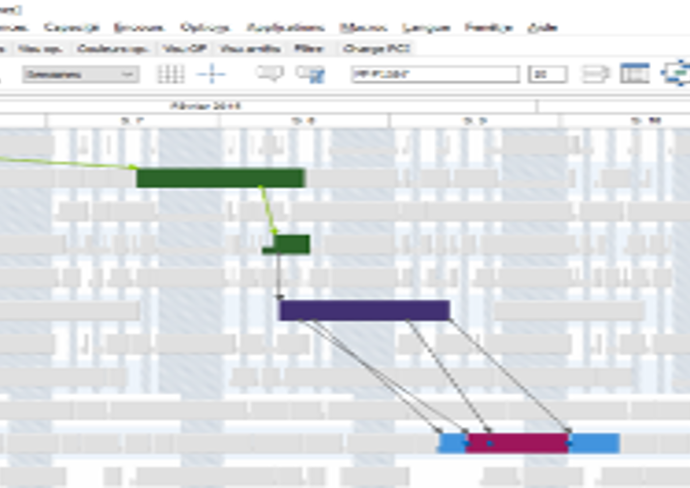

Production Scheduler

ADVANCED SCHEDULING CAPABILITIES

- Finite capacity scheduling

- Monitoring and visual alerts on soft constraints

- Intuitive and interactive user interface

- Setup times and batch grouping optimizations

- Labor allocation and overtime decisions support

- Backlog control

MULTIPLE CONSTRAINTS

- Machines, Labor

- Inventories & Supplies

- Material flow synchronization

- Set-up time, Tools …

COLLABORATIVE FUNCTIONALITIES

- Scheduler and supervisors collaboration

- Reference schedule for all the organization

- Digital continuity with dispatch lists

- User desktop

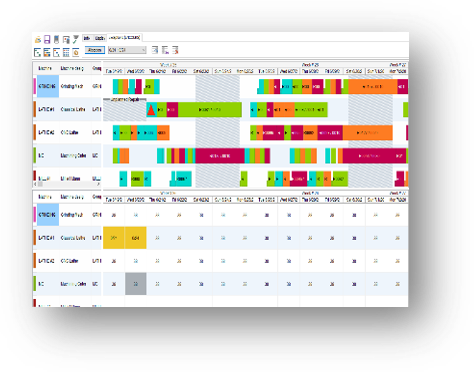

Synchronized Requirements Planner

ADVANCED MRP OPTIMIZATION

- Forecast management Vs Actual Sales

- Realistic MRP calculations at finite capacity

- Optimized order creation and lead time control

- Full pegging from raw materials to the demand

- Stock optimization in levels and coverage

MULTILEVEL SYNCHRONIZATION CONSTRAINTS

- BOM synchronization constraints

- Complex lot sizing and netting rules

- MTS and MTO strategies

- Production versions control

Synchronized Requirements Planner

UNLOCKS MRP LIMITATION

- MRP calculation at infinite capacity in ERP

- Limited constraints

- No dynamic synchronization between requirements, work orders of semi-finished, finished goods & materials

- MPS/MRP modifications level by level (cascade planning)

- Poor simulation & what if and interactive capabilities

Truly Collaborative solution

Multiple planners can work simultaneously on the same plan

DELMIA Ortems offers 3 users types:

- Planner

- Collaborative User

- Viewer

Users are concurrent users

The administration module allows you to fine-tune the rights of each user.